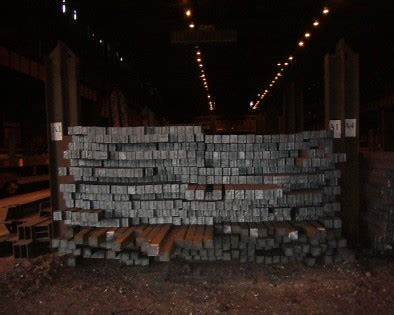

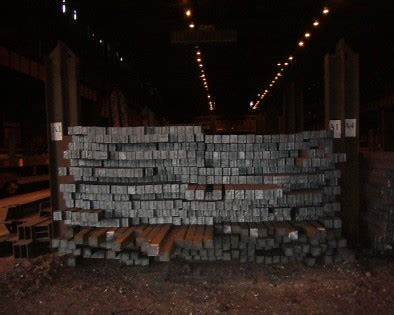

Billets produced with controlled chemistry and dimensional consistency to support downstream rolling mills and fabricators. Typical square sizes can include 130×130 mm and 150×150 mm (subject to customer requirement and production plan).

Continental Steel Group produces billets and long products at its facility in Anshas, Al Sharqia, Egypt. Current steelmaking is based on induction furnace melting with ladle furnace (LF) metallurgy. Manufacturing is aligned with Egyptian Standard ES 262-2/2015 and relevant ASTM specifications (per product scope and customer requirements). Upgrading to EAF steelmaking and adding rolling mills are under development.

Billets produced with controlled chemistry and dimensional consistency to support downstream rolling mills and fabricators. Typical square sizes can include 130×130 mm and 150×150 mm (subject to customer requirement and production plan).

Reinforcing steel supplied in accordance with ES 262-2/2015 and/or ASTM specifications as applicable. Typical size range is 8–32 mm, with final grade alignment based on customer and project requirements.

Wire rod for drawing, mesh and general applications. Typical size range is 5.5–16 mm, with specification alignment based on product scope and customer requirements.

Bars and sections supplied for fabrication and general engineering use. Dimensions and grades are aligned with customer specifications and applicable standards based on the intended use.

Standardized packing, tagging and documentation can be provided based on customer scope to support domestic delivery and export coordination.

Supply to Egypt’s domestic market and export destinations. Documentation and inspection support can be structured based on shipment requirements and customer agreements.